Standard Thai Rubber (STR)

We provided, STR20, STR10, or special grades like Low odor, Super-Control Viscosity, and Light STR10/20.

Standard Thai Rubber (STR) is a primary natural rubber product produced in Thailand through a process that involves chopping, grinding, and shredding various forms of natural rubber such as cup lump rubber, crepe rubber, scrap rolled rubber sheets, and other natural rubber scraps, which are then combined into a uniform substance. It is a form of technically specified rubber (TSR) used extensively in industries like tire manufacturing, automotive components, gloves, and construction materials

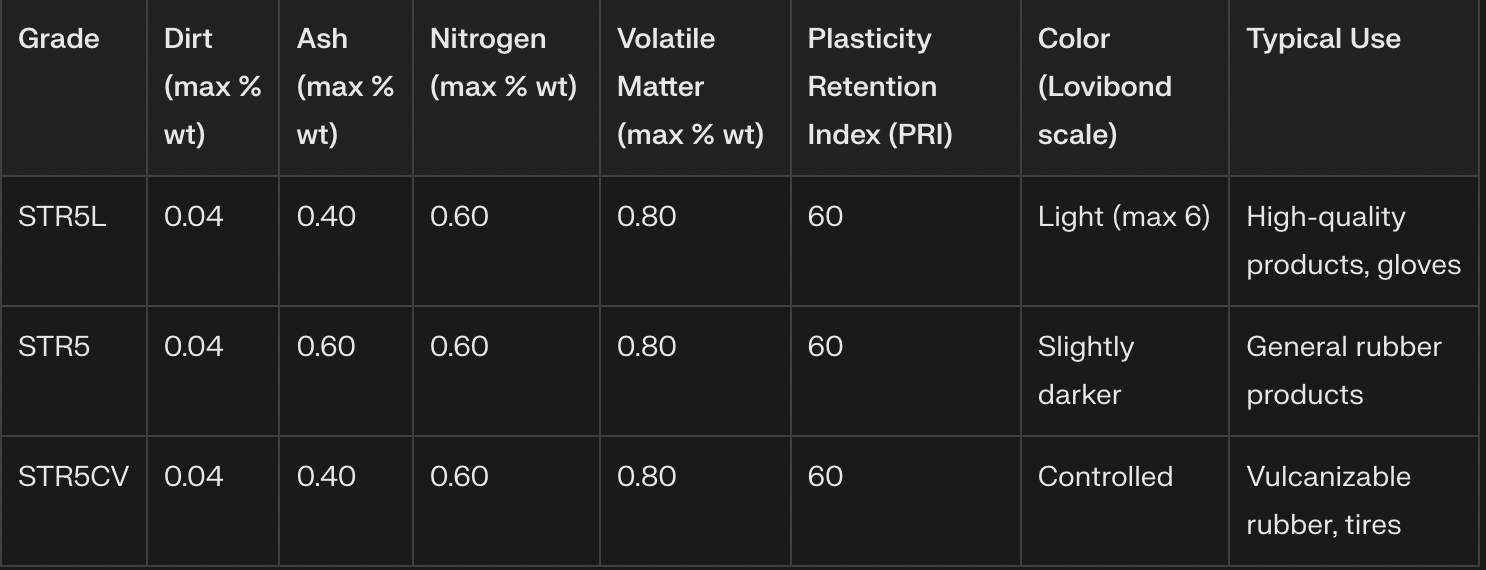

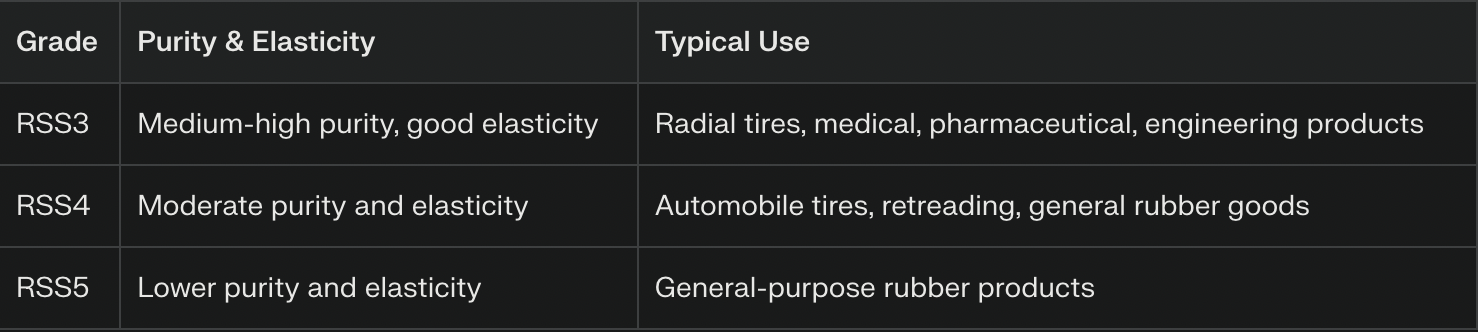

STR is categorized into several grades based on quality and physical characteristics, including STR10, STR20, STR5L, STR XL, and CV grades (e.g., CV60). These grades differ in purity, elasticity, strength, and impurity content, catering to different industrial applications. For example, STR20 is a widely traded grade known for its strength and durability, mainly used in tire production, while STR5L is valued for its low impurity content and high elasticity, suitable for medical products like glove.

The production of STR involves controlled quality processes, including laboratory testing to ensure consistency and meet specific standards. The rubber is typically packed in bales weighing around 33.33 to 35 kg for ease of handling and transportation.

Thailand’s STR is recognized internationally and compared to similar standards in other countries, such as Standard Indonesia Rubber (SIR) and Standard Malaysia Rubber (SMR)